- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

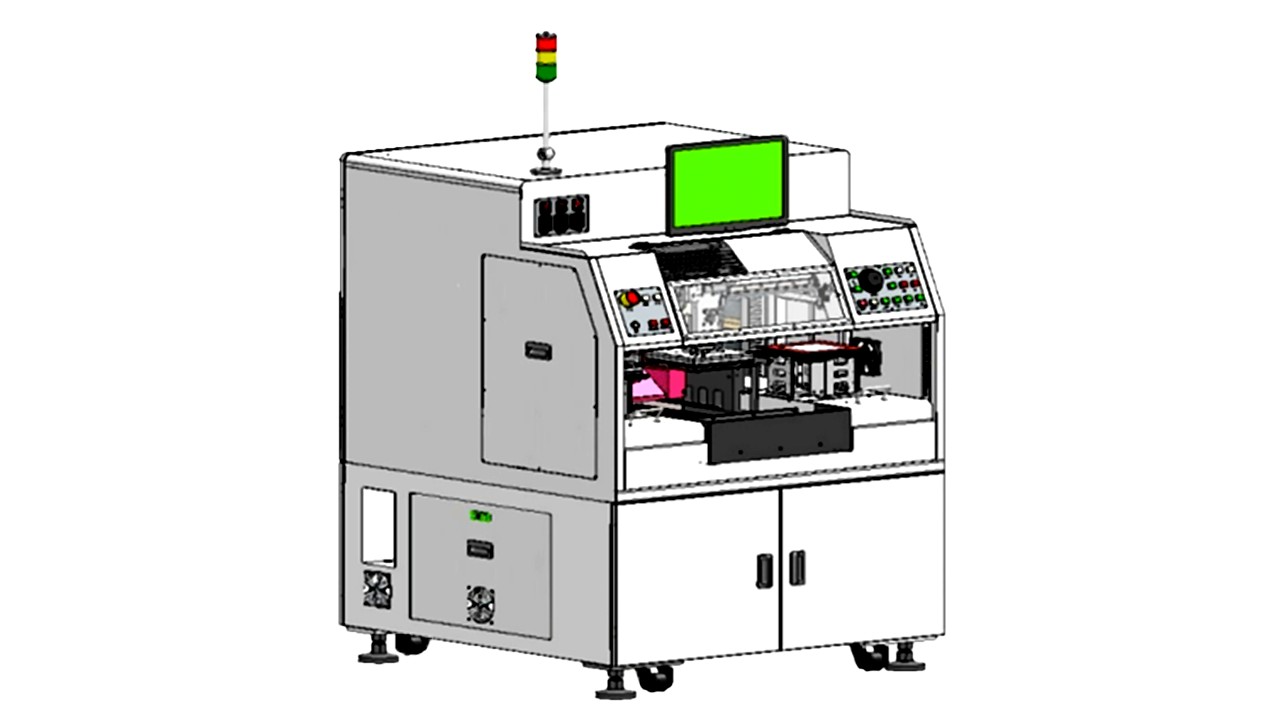

Automatic Chopping Machine

Equipment use:

This equipment is specially designed for chip component products to remove excess residual material or irregular parts on the edge of the bar.

Overview of the main functions of the device:

The equipment adopts two sets of CCD visual image systems. Through the processing of software, it can achieve automatic image search and determination and alignment mark center point, which can be used as the basis for the center position of cutting. The axis, left and right image alignment axis, and cleaning axis are composed of six axes. The image system is integrated through the image processing software to achieve the function of precision cutting.

Equipment basic parameters:

The maximum size of the equipment is about: 1250mm × 1280mm × 1700mm (excluding alarm lights)

How to order an automatic machine for your product?

Share us the picture in different angles of your product.

Share us the drawing of your product.

CONTACT US

Email:colin@xmsinuowei.com Tel:+86 18150116901

Whatsapp:+86 18150116901

Previous :

Electronic Components Automatic slitting machineNext :

chip component products Edge remove machineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Service online