- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

Features

- Fully automatic loading and unloading.

- Real-time monitoring of data, self-developed software can deliver data with customer MES system.

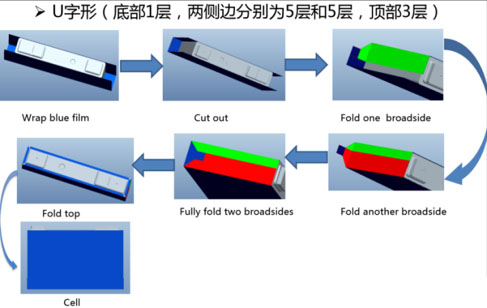

- Realize different processes of battery U-shaped pack and ring pack.

Standard configuration

The cell is inserted into the shell using the cooperation of four-axis and six-axis manipulators, flexible entry into the shell, and stable assembly effect.PARAMETER FORM

Basic parameters

parameter value

Equipment size

4.0*1.5*2.0m

Single machine capacity

6-24PPM

failure rateDT

≤2.0%

one-time advantage

>99.9%

mean time between failures

>8h

(More than 30min means downtime)

Schematic diagram of high-speed 24ppm film coating process

- In the coating station, increase the battery push into the buffer position, decompose the action of the push battery into the coating mechanism, push the battery mechanism into a double layer, push the battery to the buffer position on the bottom layer, push the battery into the film on the upper layer, and make two sets of coatings Module, complete 5 seconds to pack a battery.

- The withstand voltage test was updated from the previous double station to a 4-layer laminated structure, laying flat, and 2 sets of manipulators each clamped 2 batteries at a time to pick and place, and completed the withstand voltage test of 4 batteries in 10 seconds.

MACHINE SHOW

How to order an automatic machine for your product?

Share us the picture in different angles of your product.

Share us the drawing of your product.

CONTACT US

Email:colin@xmsinuowei.com Tel:+86 18150116901

Whatsapp:+86 18150116901

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Service online