- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

Worm Gear Hose Clamp machine with automatic band housing screws assembly

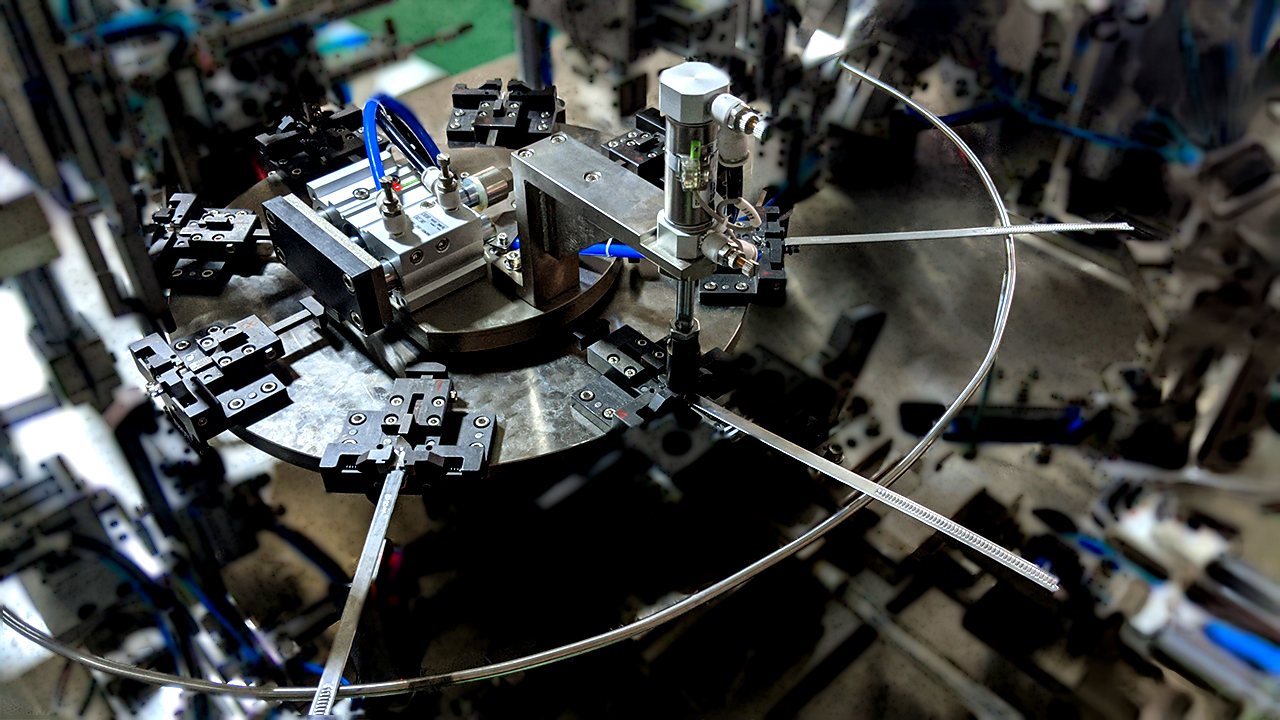

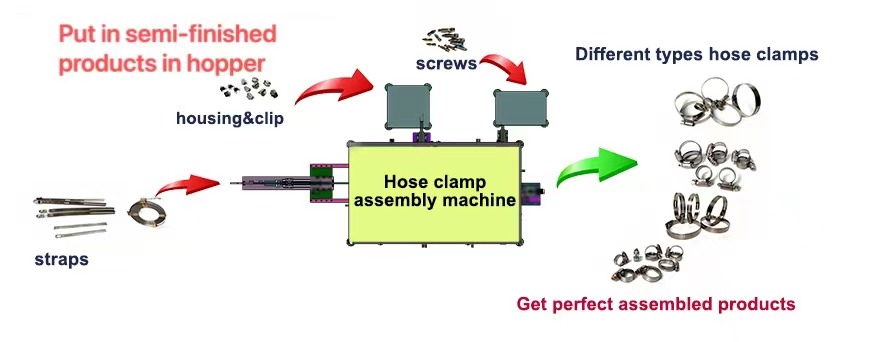

hose clamp automatic machine manufacturers can fully assemble hose clamps through straight lines and turntables. Screws, connecting strips, clamps, hoses and other parts are all assembled by machine rolling, locking and forming. Double stations ensure higher productivity.

Item no.:

hose clamp machine88Payment:

FOBMarket price:

$90000Price:

$70000/setsPrice range:

40000 - 90000/$1Product origin:

ChinaShipping port:

XiamenLead Time:

90High-precision German hose clamp manufacturing machine manufacturer hose clamp automatic assembly machine is sold at a competitive price

This German-style hose clamp machine can automatically assemble hose clamps through straight lines and turntables. Screws, connecting bars, clamps, hoses and other parts are assembled by machine rolling, locking and forming. Sinuowei's machine and process control system is a new patented design, using fully automated cutting and stamping, welding and intelligent mold solution technology. Our hose clamp make machine not only maximizes production efficiency and quality, but also reduces a lot of costs for hose clamp manufacturers. This machine is advanced, high level of automation, stable performance, wide adjustment range, high efficiency and good effect.

| product name |

Hose clamp machine |

| size | 2600mm (length) *1200mm (width) *1800mm (height) |

| weight | 1 ton |

| working area | 5000mm(length)*3000mm(width) |

| strength | Single-phase power supply 115v, 60Hz (ANSI electrical standard) |

| pressure | 0.5Mpa-0.8Mpa |

| Free torque | <=0.45 |

| breaking torque | More than 7-13N/M |

|

Equipment failure rate |

Less than 0.5% |

| efficient | 700-1200 pcs/hour |

| warranty period | One year |

| Extra service | Professional technical training |

|

Major component brands |

Japan SMC, Germany SIEMENS, Japan Panasonic, Japan Keyence, France Schneider, Germany BASLER, Taiwan HIWIN. |

|

1. We have sold hundreds of machines at home and abroad, and they are running well so far. As time goes on, our machines become more precise, more efficient and more stable. |

|

2. We are professional in design and manufacture automatic assembly hose clamp machine with 10 years of experience. Our technology of automatic assembly hose clamp machine is mature and reliable. |

|

|

3. The production efficiency is 1000pcs/hour more or less and working accuracy are all much higher than handmade, therefore satisfying the production requirements of new generation manufactures of hose clamp. |

|

|

4. An automatic assembly hose clamp making machine can be designed as Multi-size according to client's requirement. Maybe two or four different sizes in one machine is available if the structure of clients' hose clamp allowed. |

|

|

5. The same as another many parameters of machine, Free torque and broke torque of hose clamp can be customized. Our flexibility customization design to ensure all customer's requirements are met. |

|

|

6. Compared with the traditional manual control manner, this machine has many advantages such as stable and simple operation. Working content is only adding semi-finished product material on bin every 4 hours. |

|

7. The production is controlled by PLC microcomputer which will records all data and it equipped with human-computer interface to make sure most all the technical parameters can be set on the touch screen. |

|

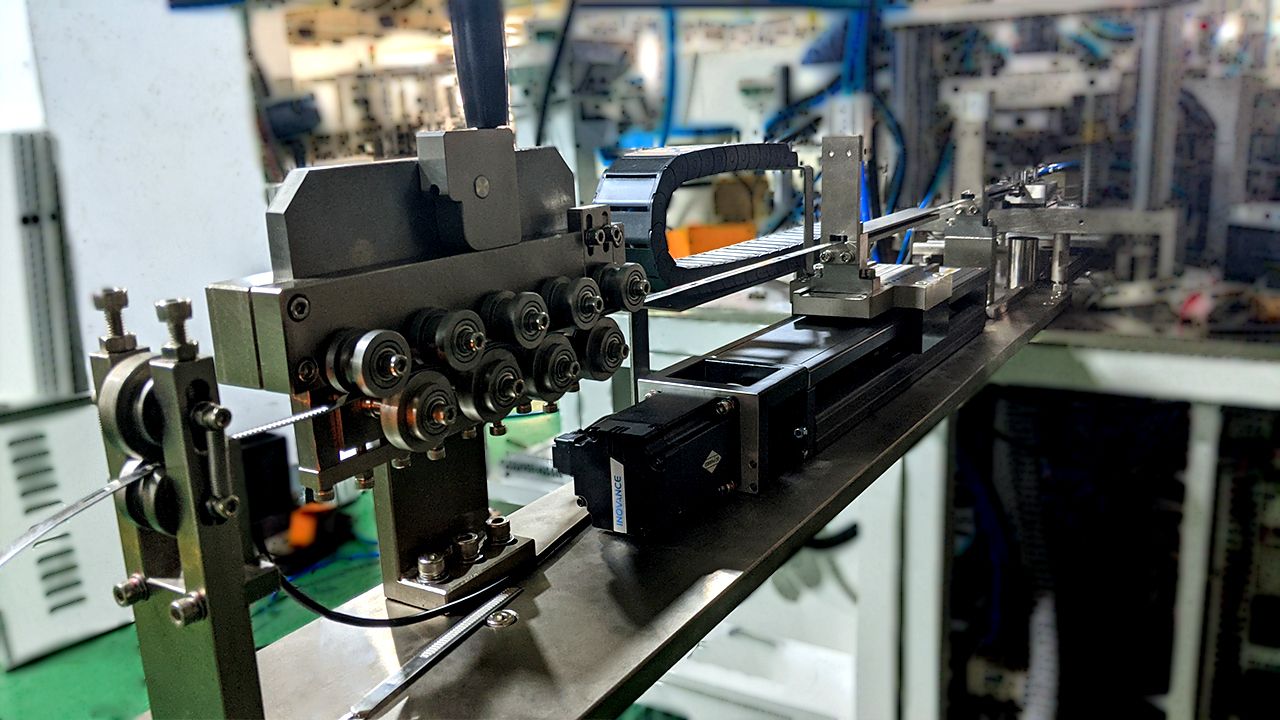

1. The strap will be transferred into the machine directly in one direction through the automatically flatting system. What follow is entering strap will be cut into right size and to be punch in right shape. |

|

|

2. The housings and clip of hose clamp will be transferred into the machine directly in one direction as well by vibration linear feeder with bin. They will be installed into the punched and cut strap firmly. |

|

3. The strap of hose clamp with housing and clip will be coiling by our machine in very perfect circle and to be fixed by tooling system and then transfer into next step smoothly. |

|

|

|

4. The screw of hose clamp will be transferred into the machine directly in one direction by vibration linear feeder with bin. The screws to be tighten into the assembled strip of hose clamp with housing and clip. |

|

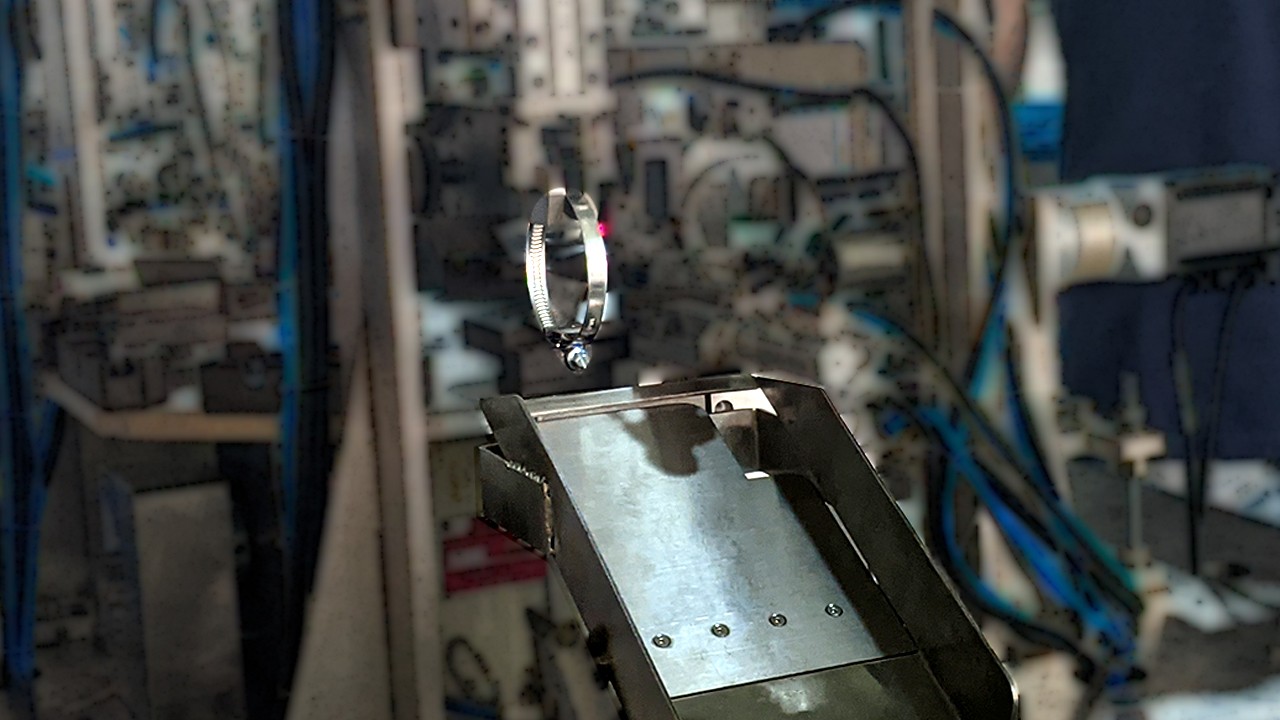

5. After the above steps, a hose clamp is completed. The discharge port is equipped with a detection system to confirm whether the finished product is locked and whether the free torque fully meets the requirements. |

|

|

|

6. The final product is grabbed from the fixture and automatically divided into two categories, good and bad. Good products flow into the good product container, and bad products flow into the defective product container for collection. |

Previous :

British Hose Clamp Automatic Assembly MachineNext :

High Accuracy German Type Hose Clamp Making Machine Manufacturer Hose Clamp Automatic Assembly Machine In Competitive Price For SaleIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Service online