- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

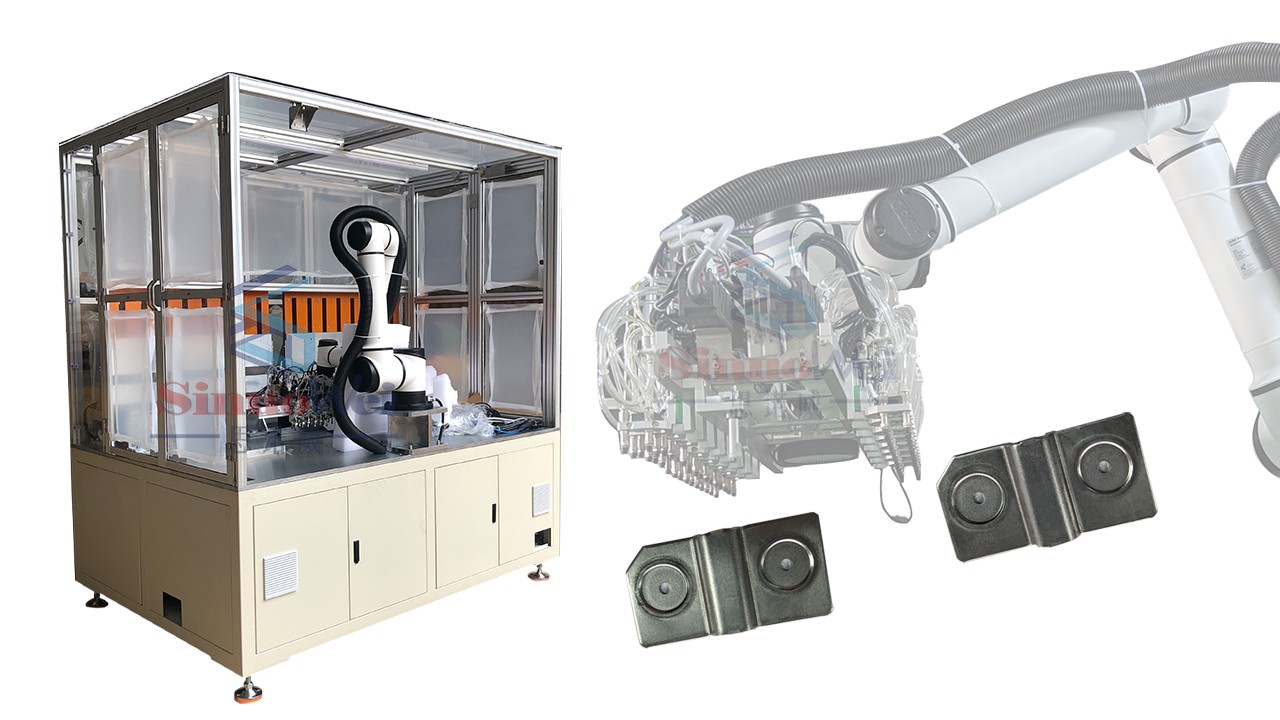

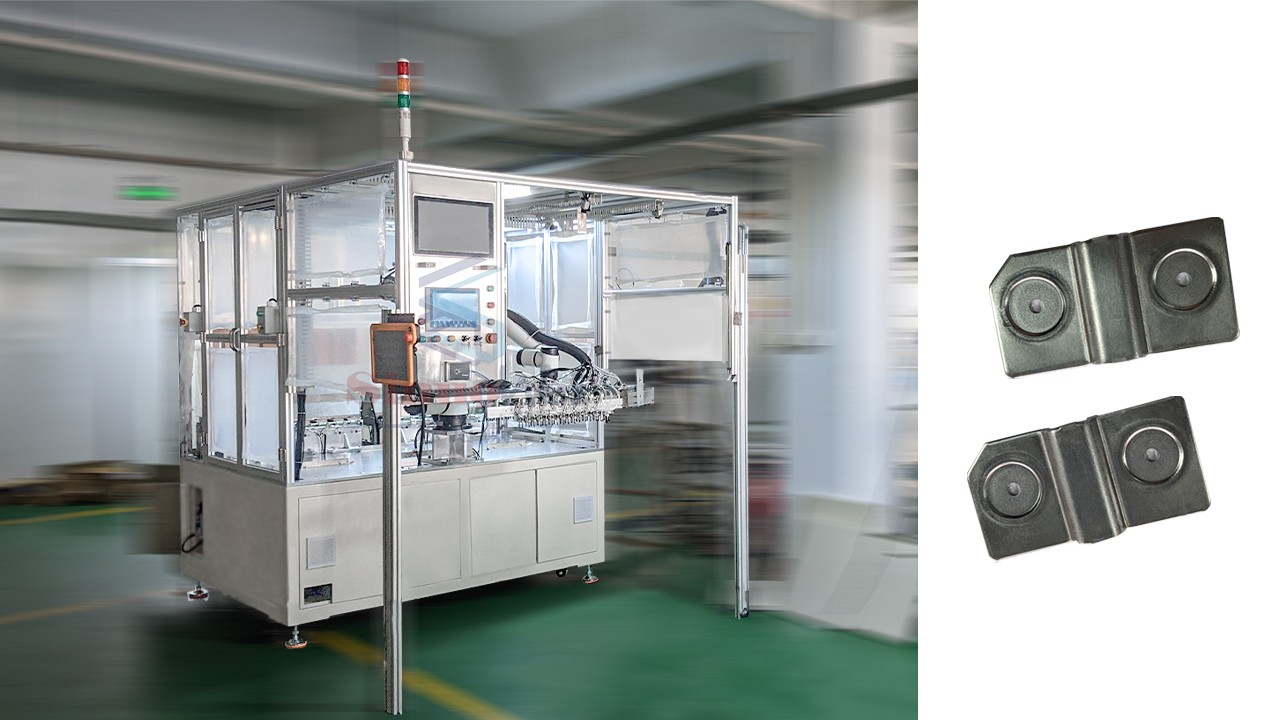

This equipment is used to realize the collaborative robot to clamp the palladium sheet and place it on the module tooling. Its structure mainly includes the collaborative robot, palladium sheet clamping mechanism, palladium sheet feeding mechanism, palladium sheet buffer mechanism, and CCD re-inspection system. CCD vision captures feature points and finds the placement position of the palladium sheet. After the palladium sheet is placed, it will be re-inspected by CCD vision to determine whether the placement of the palladium sheet is qualified to ensure the reliability of the next station.

Product Parameters:

|

Equipment name |

Fully Automatic Palladium Sheet Automatic Loading Machine |

|

Pressure |

0.5-0.8MPa (72.5-116.0 PSI) |

|

Equipment size |

Designed according to customer requirements |

|

Equipment weight |

2-5t |

|

Installation location: |

dust-free workshop, equipment noise index ≤75dB, copper, nickel and zinc prohibited |

|

Working cycle: |

12ea-25s 26ea-45s |

|

Positioning accuracy: |

dust-free workshop, equipment noise index ≤75dB, copper, nickel and zinc prohibited |

|

Product compatibility: |

Length: 50mm-90mm and above Width: 30mm-50mmm and above Height: 5-10mm |

|

Equipment failure |

<0.3% |

|

Warranty period |

1year |

|

Additional services |

Professional technical training |

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Service online