V9 CNC Electrostatic Powder Spray Gun

V9 CNC Electrostatic Powder Spray Gun

V9 Performance Introduction

Full numerical control programmable electrostatic powder spray gun, and single gun on the remote control

Powder amount size for manual and automatic gun control. On the one hand, the controller has three standard pre-stored programs

On the one hand, the controller has three standard programs pre-stored, which are specifically designed for spraying flat workpieces, complex workpieces and re-sprayed workpieces. On the other hand, the user can precisely control the voltage, spray current, powder output and total air volume at the touch of a button. Up to 20 programs can be stored.

How to Use

Please connect the ground wire first before turning on the power supply.

Wait 5 seconds before pressing the power on button after the 220V power is turned on for the first time, and wait 10 seconds for the 110V power. After the host starts, if you press the key, the passive interface will display the set value of each data, and the actual value will be displayed after 3 seconds, and the system will save all the current data.

Input Key Function

No.

Function

1

Add or subtract powder

2

Nebulization plus or minus

3

electrostatic additions and subtractions

4

cleansing gas plus or minus

5

Program selection plus or minus

6

New Workpiece Coating Patterns

7

Notched Position Spray Patterns

8

Coating mode for repetitive sprayed parts

9

Program switching key (manual and switching between three modes)

10

Secondary menu switching key (setting cleaning gas)

11

Static switch key

12

work instruction

13

power-on indication

14

power indicator

15

Powe key

16

Fluidization control

17

Fluidizing Pressure Indicator

Back Interface Function

No.

Function

1

220VAC power cord

2

Single Gun Control Line Interface

3

Mainframe Ground

4

Air input 2. φ8 connector

5

Powder pump powder quantity interface φ8

6

Powder pump atomization interface 6

7

Electrode needle cleaning gas port φ4

8

Powder drum fluidization interface φ6

9

Air Input 1. Quick Connector

10

φ8 gas pipe connection "4" and "11"

11

φ8 connector

PARAMATER FORM

Electronic controller systems

Built-in electrostatic spray gun

Pneumatic control systems

Input voltage: 220V/110V

Input voltage: 12V

Solenoid voltage: 24VDC

Input frequency: 50HZ

Input frequency: 35KHZ

Input air pressure: 5.5-8bar

Input power: 46W

Input current: ≤0.6A

Compressed air moisture: ≤ma*1.3/NM3

Output voltage: 12VDC

Output voltage: -100KVDC

Compressed air oil content: ≤ma*0.01g/NM3

Output current: 0.1A-1A

Output current: 0-100UA

Air flow: ma*19g/NM₃

Valve control voltage: 24VDC

Connection cable: 5M

Input cable: 2.5M

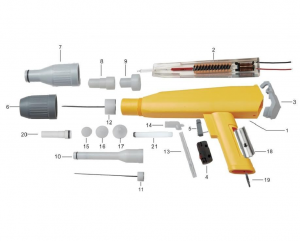

List of configurations for a single set of powder guns:

1. a host

2. a single gun

3. a set of flat nozzle, venturi

4. environmentally friendly silicone powder tube

5. high-flow powder pump a

6. connection PU tube

7. a stainless steel powder barrel

8. a set of electrode holder

9. a set of large, medium and small nozzle

10. a mobile cart

11. a ground line

12. a set of extension rod