- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

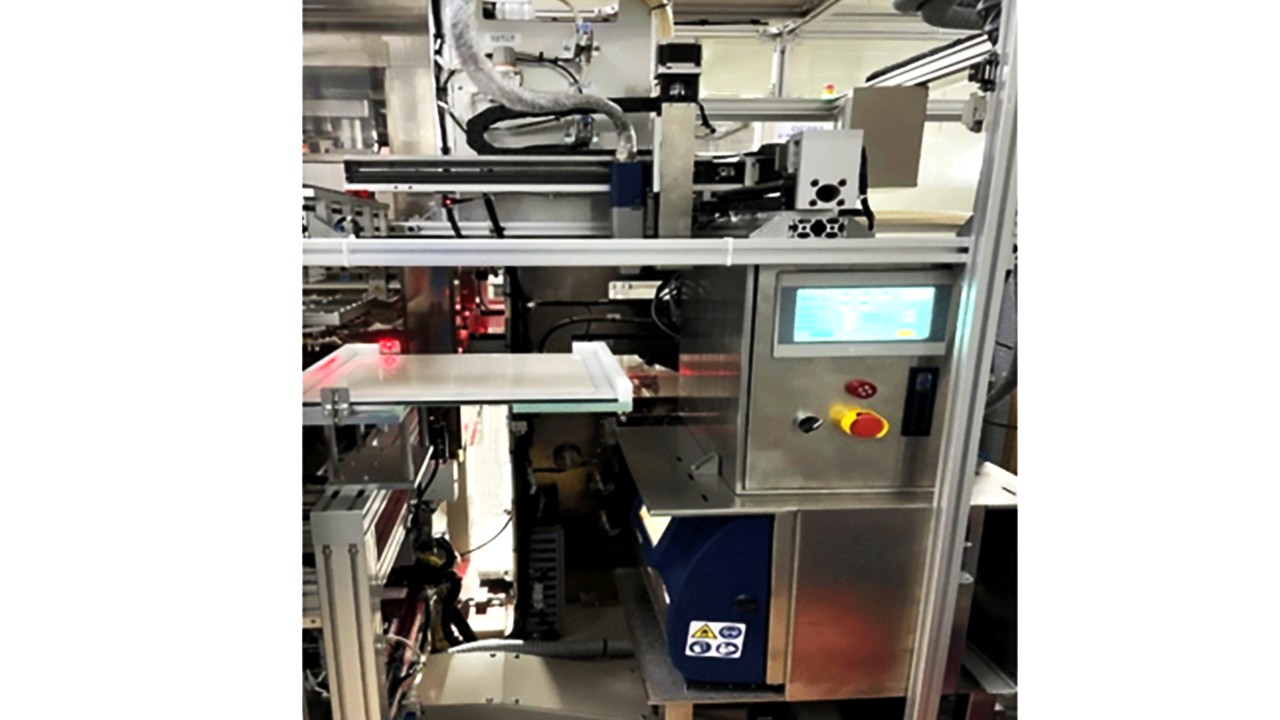

QR code inkjet printer

Equipment use:

Through the transformation of the laminating machine, the two-dimensional code is sprayed on the block after the lamination is completed, which is convenient for the production management of the block during the turnover process of lamination, lamination and cutting. The imported first-line brand Domino Ax150i inkjet printer is selected, which has high inkjet efficiency and less manual intervention. The nozzle supports automatic cleaning and is maintenance-free. The inkjet content can be configured through the touch screen or MES system.

Equipment basic parameters:

Size of block to be sprayed: 310mm×310mm

Support coding range: 2×2, 4×4

Coding format: QR code + alphanumeric + symbol

Operation mode: The seven-inch touch screen of the control cabinet sets the action, and the seven-inch touch screen of the inkjet printer controls the content of the inkjet.

How to order an automatic machine for your product?

Share us the picture in different angles of your product.

Share us the drawing of your product.

CONTACT US

Email:colin@xmsinuowei.com Tel:+86 18150116901

Whatsapp:+86 18150116901

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Service online