- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

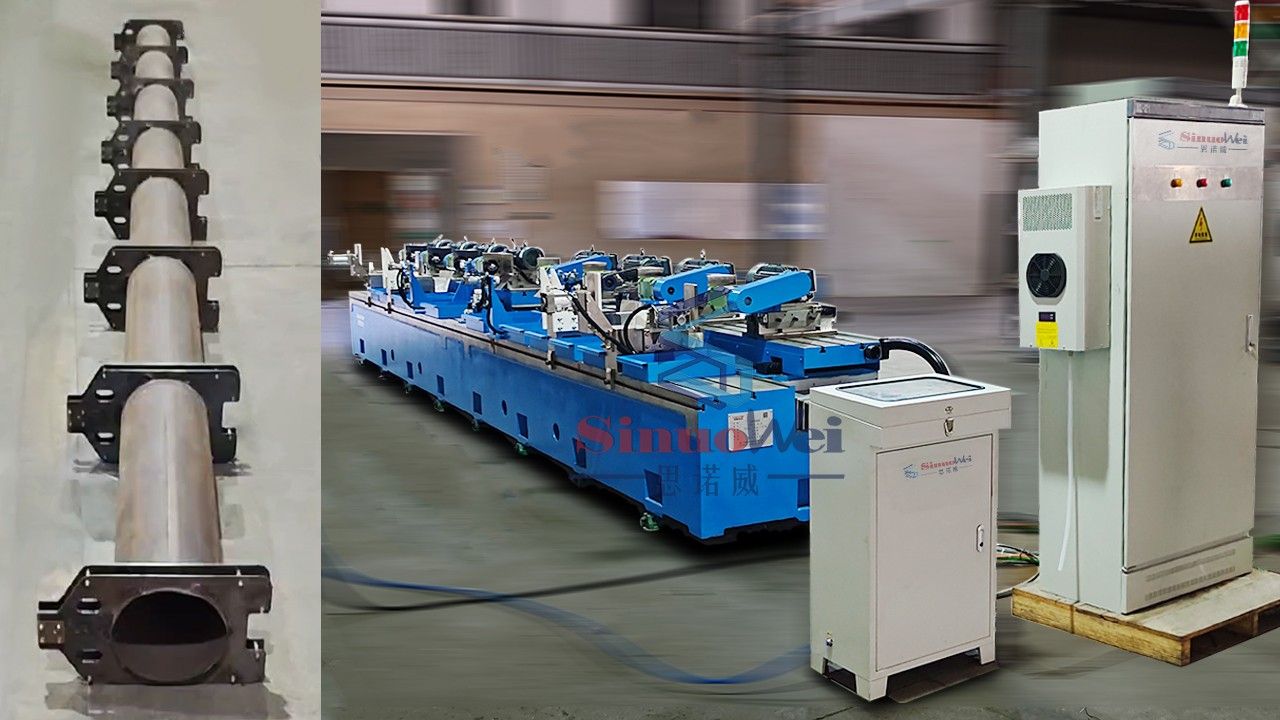

This equipment is used for drilling holes in main beam welded parts.

This equipment is used for drilling holes in main beam welded parts. Adopting PLC control, it has two processing modes: automatic processing and manual processing, and the two processing modes can be switched freely. The manual mode has the functions of manually controlling the clamping and loosening of the clamping mechanism, jogging of the feeding mechanism, step drilling, and fast retraction. The automatic mode has the functions of fully automatically completing the whole process from clamping mechanism positioning and clamping, drilling, fast retraction, clamping mechanism loosening, and waiting for unloading after the start button is pressed.

Usage Environment Requirements:

|

Parameters |

Working Environment |

Storage Environment |

Transportation Environment |

|

Temperature |

-10ºC~40ºC |

-40ºC~65ºC |

-40ºC~65ºC |

|

Humidity |

5%~85% |

5%~85% |

5%~85% |

|

Altitude |

≤5500m |

≤5500m |

≤5500m |

Product Parameters:

|

Project |

Parameters |

Remarks |

|

Equipment Size |

≤(20000×9000×5000mm)L W H |

Including auxiliary equipment |

|

Processing efficiency |

Single main beam processing time (including loading and unloading) ≤ 4 min (punching time < 2 min, loading and unloading time ≤ 2 min) |

/ |

|

Operators |

1 person |

Excluding auxiliary personnel |

|

Power |

≤20000w |

/ |

|

Maintenance Performance |

Maintenance-free or easy to maintain, parts have good interchangeability |

/ |

|

Defective rate |

≤0.3% |

Caused by equipment |

|

Power supply |

Three-phase four-wire 380VAC±10%, 50Hz±2% Customized according to customer's regional requirements, electrical components meet export standards |

/ |

|

Air source requirements |

Pipeline end pressure ≤ 0.7MPa |

/ |

|

Positioning accuracy |

≤0.02mm |

/ |

|

Repeat positioning accuracy |

≤0.008mm |

/ |

|

Control system |

PLC control, with touch screen |

/ |

|

Purchased components |

Preferred components require use of mainstream brands from Taiwan or abroad |

/ |

|

Service life |

Service life is greater than 10 years. A list of wearing parts and maintenance and replacement cycles are required |

/ |

Machine Show:

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Service online