Robotic welding is a relatively new application of robotics, although robots were first introduced to American industry in the 1960s.

The use of robots in welding did not take off until the 1980s, when the automobile industry began to use robots extensively for spot welding.

Since then, the number of robots used in industry and the number of applications has greatly increased.

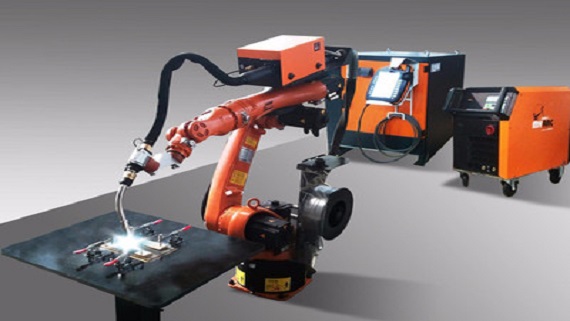

With the continuous development of robot welding technology, the welding robot has become more and more intelligent and automatic. At present, the general welding operation is easy for it to complete. Then, do you know the operation steps of precision welding of the automatic intelligent welding robot?

1. Generally, when conducting precision welding, the electrode rod needs to be adjusted to the corresponding position to make the motor just touch the welding parts, so does the welding robot.

In addition, it is necessary to keep the electrode arms balanced so that good welding quality can be obtained.

2. The selection is mainly based on the thickness and material of welding parts. When the welding robot is energized, the power indicator light will go on.

How to set a reasonable electrode pressure? The main method is to adjust the spring pressure nut so that the compression stroke can be changed.

3. After the completion of the above adjustment, the welding robot can officially start the welding operation after the power and water source are connected.

By placing the welding piece between the two electrodes, the robot automatically puts the upper electrode in contact with the welding piece and pressurizes it. The transformer then starts to heat the welding piece.

4. When the welding robot completes the precise welding, the electrode of the welding robot rises to make the spring pull, thus cutting off the power supply and restoring the original state. Such a welding process is considered as the end.

Welding robot has made a great contribution to the development of the manufacturing industry. It is now able to complete precision welding procedures, and I believe it can complete more complex welding parts in the near future.

The welding robots rescued people from a hostile environment.

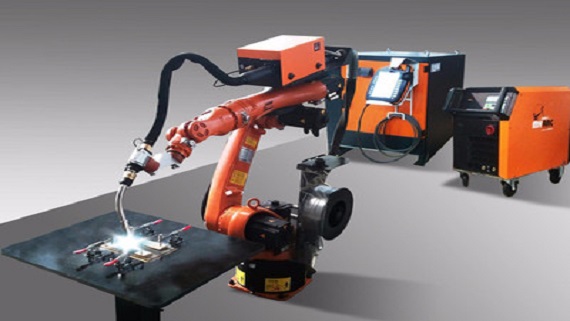

Automated welding technology is advancing rapidly, and robotic welding guns are becoming more accurate, longer-lived and more cost-effective.

Focus on the research of welding gun every detail, so that its production of robot welding gun and related parts to obtain a high cost performance.

It has been widely used in the field of robotics.

1. When installing parts connected with threads such as conductive nozzle, conductive nozzle base, gas separation ring and flame mouth, please properly correct the corresponding threads and then tighten them gently and smoothly so as to obtain good electrical conductivity.

2. For water-cooled welding gun, due to intermittent welding, the lock nut alternated between cold and hot, which may lead to loose thread, discharge and burning loss due to the gap between the body and the cable, so check and tighten the lock nut regularly every week.

But don't push so hard that it slides.

3. If leakage occurs at the cable flange, please timely check whether the body is properly installed. If the contact surface of the body cable has been damaged, please send it to the manufacturer for repair in time.

4. The water-cooled welding gun should be fully cooled when working. Please check the water tank, water inlet pipe and water pipe should be smooth, and they should not be bent or tied.

5. The robot welding gun is a consumable material in the welding system. It is recommended that users prepare the welding gun inventory in time for replacement during maintenance without affecting production.